Monthly Insights

Practical manufacturing news with our take!

December 2025 Closeout

Structure, Hierarchy & Productivity: Why Leadership Makes the Difference

This month we’re going to close the year with a topic that affects nearly every manufacturing business: Organizational Structure. Whether it’s a traditional hierarchy, a layered org chart, or a unionized environment, structure is meant to bring clarity and stability. But as many companies experience, the impact on productivity has far less to do with the chart itself and far more to do with the leadership behind it.

When leaders create bottlenecks, restrict communication, or fail to empower people closest to the work, even a simple structure becomes rigid and slow. Conversely, when leadership encourages autonomy, accountability, and problem-solving, the very same structure becomes a powerful enabler of efficiency.

The same dynamic applies in union environments. Strong labor management relationships improve safety, reliability, and long-term workforce stability. But when leadership becomes political, disconnected from the floor, or overly protective of “the way things have always been,” productivity suffers not because of the union, but because collaboration breaks down.

Structure doesn’t determine performance. Leadership does. We found ourselves in an organization that had an amazing performance review system with great structure only to find out it was just smoke and mirrors. If you have it use it!

The healthiest organizations maybe union or non-union are usually the ones where people feel trusted, informed, and empowered to solve problems at the point of impact.

Our Take:

Org charts don’t hurt efficiency poor leadership and poor communication and not being honest does.

Empowered teams outperform over managing teams, regardless of hierarchy.

Productivity increases when structure is treated as a support system, not a control system.

A manager works with people in the business and a leader works on the people in the business. Both take a great amount of effort and one makes a greater impact. Stop managing and start leading!

~ PIO Products LLC

November 2025

The Cost of Slow or No Decisions: Why Speed Matters in Manufacturing

The competitive edge belongs to companies that make decisions quickly and confidently.

Not recklessly but without delay.

In manufacturing environments where technology, customer expectations, and labor demands are evolving faster than ever, slow decisions have become bottlenecks and one of the most expensive forms of waste. Projects stall, talent disengages, opportunities slip, and teams lose momentum while waiting for approvals that should take hours, not weeks.

What we’re seeing is that speed is no longer just operational, it’s cultural. High-performing organizations empower employees to act, remove layers of approval, and reward initiative. Meanwhile, companies with excessive committees, over analysis, or indecisive leadership often experience productivity drag that no amount of equipment or software can overcome.

The months insight is straightforward:

In today’s manufacturing market, the ability to decide is as valuable as the ability to produce.

Our Take:

Slow and sometimes over analyzed decisions create hidden costs, lost time, lost engagement, and lost opportunities.

Empowered teams make faster, better choices because they operate closer to the work. Train them to think and act like an owner.

Competitive advantage now favors organizations that move with clarity, trust, and urgency.

~ PIO Products LLC

October 2025

When 400,000 Manufacturing Jobs Go Unfilled, It’s Time To Rethink The Blueprint

Based on Natan Linder, Forbes, Sept 22, 2025

Nearly 400,000 U.S. manufacturing jobs remain unfilled, despite steady demand and competitive wages.

Old labels like “blue collar” vs. “knowledge work” no longer reflect the reality on factory floors — frontline operators are solving complex problems every day.

Traditional manufacturing execution systems (MES) and rigid digital stacks often slow workers down, rather than empower them.

To close the talent gap, the industry needs to:

Invest in user-friendly, modular tech designed for frontline use.

Reframe job design to highlight the cognitive and problem-solving skills required.

Treat factory work as smart work, not secondary to office roles.

The future is a “collar-less” workforce, where contribution is measured by skill and adaptability, not by outdated labels.

Our Take:

At PIO Products, we see the same story playing out across Michigan shops and the wider industry:

Tools matter! Many shops rely on many softwares. We push for lean documentation, intuitive calculators, and visual SOPs that keep the work focused where it belongs in machining, not clicking through menus.

Talent is already in the shop Instead of chasing a “silver bullet hire,” owners should empower existing teams with continuous training, process improvement tools, and clear problem solving framework. We’ve watched small shops make huge gains just by giving machinists ownership in setup sheets, tool libraries, or Lean projects.

Respect the role. Manufacturing isn’t fallback work. It’s highly technical, creative, and impactful. When shops brand themselves this way, they recruit better talent and keep people engaged. Many companies don’t empower or model this behavior.

Opportunity ahead. Shops that adapt their technology and culture will win the next wave of workforce competition. The ones that cling to rigid systems and outdated hierarchies will keep struggling to fill open roles.

The labor gap isn’t going away by simply finding more people. It will be solved by empowering-paying the people we already have, modernizing tools, and respecting shop-floor knowledge as the real driver of manufacturing excellence.

~ PIO Products LLC

September 2025

CAM Copilots and the Next Digital Shift in American Machining

In September’s issue of Modern Machine Shop, Brent Donaldson explores “CAM Copilots and the Next Digital Shift in American Machining.” His article highlights how AI-powered copilots are entering the CAM space, reshaping workflows, and accelerating toolpath creation.

Having spent 18 years using Mastercam professionally in industry and 12 years teaching it at the college level, I’ve seen firsthand how critical it is to balance new digital tools with fundamental knowledge.

I began by self-training on Mastercam V9, learning its logic step by step. That foundation has been the backbone of my engineering and instructional work while providing a stable, rewarding career. Over the years, each revision of the software brought new efficiencies, but it was always essential to understand how algorithms generated toolpaths, feeds, and strategies before trusting the output.

AI copilots promise to reduce the learning curve and make CAM more accessible. But here’s the catch: jumping straight into AI without understanding the basics risks shallow proficiency. True mastery requires knowing why a toolpath behaves a certain way, how machining dynamics interact, and how to adjust strategies when things go wrong.

Our Take:

Just as I matured alongside Mastercam’s releases, machinists and programmers today must develop alongside AI. Use them as accelerators but pair them with core skills. That’s where the long term advantage lies for American machining: blending craftsmanship, fundamentals, and the newest digital copilots into one evolving toolkit

AI copilots are transformative but fundamentals remain the backbone of machinist education.

Training should focus first on how CAM software thinks, then leverage AI for speed and efficiency.

The real shift is not just faster toolpaths, but smarter machinists who can mature with technology.

Continuous education and staying up to date with these applications and technology is key!

~ PIO Products LLC

August 2025

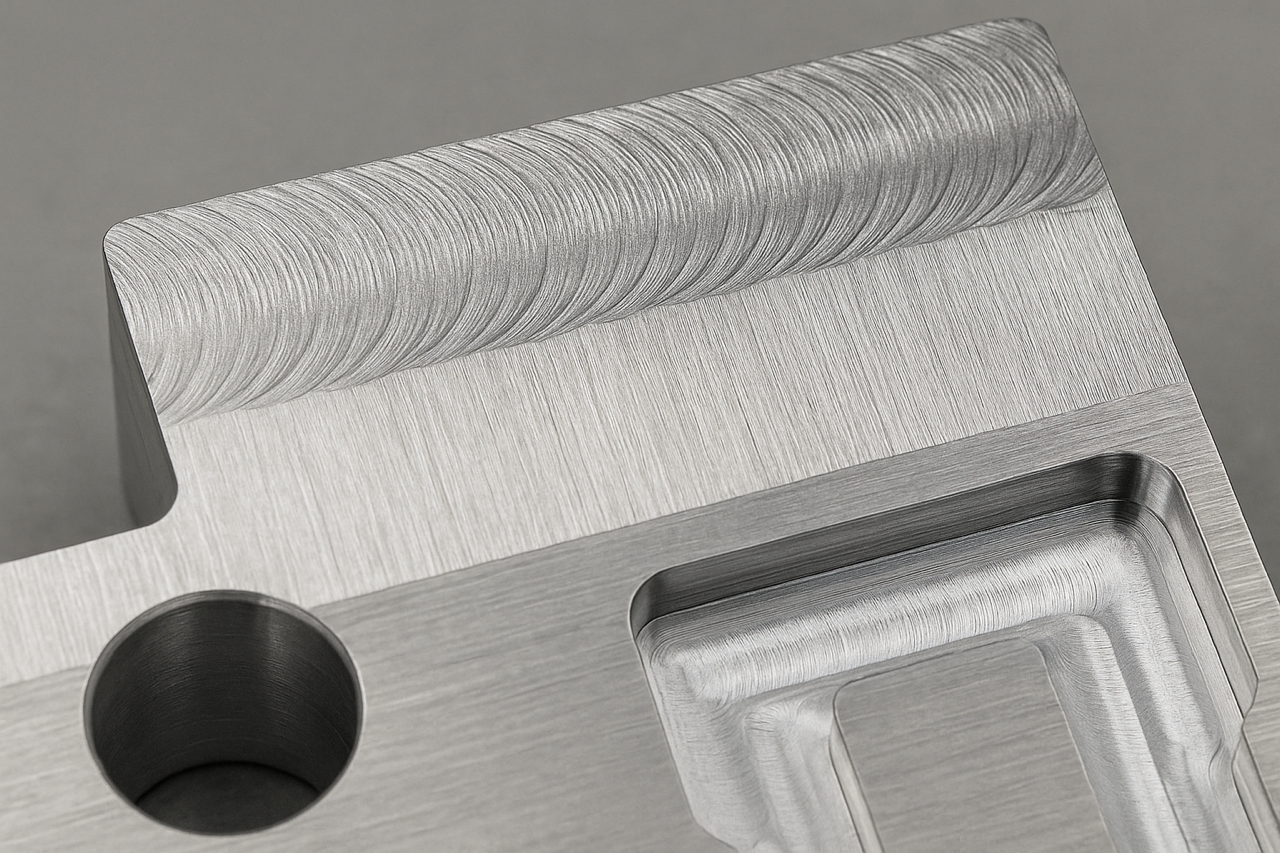

Preserving the Craft: Blending CNC Fundamentals with Modern Tech

As automation, AI, and CAM continue to accelerate CNC machining workflows, are we unintentionally phasing out the core skills that built this industry?

This month, we reflect on “Preserving the Craft” by John Miller (Modern Machine Shop, August 2025), a timely reminder that as technology evolves, it should complement, not replace, the fundamentals of precision machining.

Key article Insights:

1. Understand G-Code — Don’t Just Click “Post”

Even with advanced CAM and AI-generated toolpaths, being able to read and edit raw code is still critical. It empowers machinists to:

Catch post-processing errors

Modify toolpaths during troubleshooting

Develop probing cycles and macros confidently

2. Hands-On Setup Still Matters

Software can guide, but only physically torqued toolholders, properly cleaned tapers, and trammed fixtures build long-term process control and minimize downtime.

3. Rigidity Wins in Production

Modular and flexible setups are great for prototyping, but when scaling up, heavy-duty, stable workholding and fixturing consistently deliver better part quality and tool life.

4. DFM Is Still a Human Skill

Software can highlight red flags, but only experience can identify uncuttable corners, awkward tool access, or unrealistic tolerances. Design for Manufacturability lives between the print and the floor.

5. Intuition Isn’t in the Cloud

A seasoned machinist can hear when a cut is wrong or feel when something is off. That kind of awareness can’t be automated — and is often the first line of defense against scrap and spindle damage.

Our Take:

Technology enables, but we are the anchor. CAM, AI, and automation are powerful tools but they work best on a stable foundation of core skills. Without those, you’re scaling noise.

Lean isn’t just software it’s skill standardization. True Lean relies on repeatable human practices such as setup techniques, DFM review, tool care, and process intuition. These aren't “old-school,” they’re essential for standardized work.

Some actionable ideas for your shop:

Host monthly fundamentals trainings or check ins: Spindle runout checks, fixture tramming, manual tool touches, probe calibrations.

Build a technical knowledge base in your shop: Manuals, G-code examples, probing templates, etc.

Encourage peer mentorship: Match seasoned machinists with new talent during critical jobs. Deter tribal knowledge or knowledge hoarding behavior.

Our final thought. You can’t automate good judgment. When things go wrong it’s the fundamentals that bring everything back in line. Reach out if your looking for help to build a sustainable-repeatable process.

~ PIO Products LLC

July 2025

1. Modern Machine Shop: “High-Efficiency Milling in the Real World”

Key Insight: It’s not just about tool speed—it’s about toolpath strategy, engagement, and rigidity.

Our Take: This is a great article! We’ve seen shops dive into high-efficiency milling without adjusting feeds, holders, or accounting for chip evacuation—then wonder why tools fail. OEMs often provide great starting points, but it’s essential to collect data on your tooling for all your applications. You maybe reducing cycle times while killing tool life and increasing your cost of consumables. Sometimes all you need is the right endmill, holder, tool body, or inserts—but more often, there’s other factors at play.

When you’re ripping material at high rates, vibrations-harmonics matter. Shifting to adaptive or dynamic toolpaths, we recommend increasing finish stock, recalculating chip loads, verify holder types, minimize projections, and check the overall assembly for deflection. Rigidity is key. Who knows, your spindle could be washed out also causing tools to pre-maturely wear. Most importantly—COLLECT PERFORMANCE DATA! You paid for it. A high-performance setup can easily cost $400-600 per station. Many machines equipped with 20-40 stations. $15,000 on average. Why wouldn’t you want to understand the tool life and or the cost per edge? Reducing vibration and extending tool life is easy and often overlooked.

We’ve sourced and implemented many solutions from all the leading OEMs. Let us know your application challenges and we’ll guide you in specifying, testing, and collecting the data. Also, be sure to check out our calculators under the resources tab.

2. SME: “How Small Shops Are Leveraging Automation Without Robots”

Key Insight: Automation doesn’t always mean robots. Think: probe cycles, CAM templates, automatic inspection macros.

Our Take: This one hits home. This article has been taken down. I’m assuming it’s due to paid advertisements (robot automation)? Some of the biggest efficiency gains for small shops isn’t always a large capital investment and or maybe your shop doesn’t have the capital. Have you leaned all your processes out? Some of your automation can come from code-level and utilizing your current machine tools. We can deliver custom macros, probing macros, CAM templates, and standardize setups potentially cutting your changeovers in half. We have a few solutions up our sleeve that could cost you 80% less than your average pellet change or tending system. Ready to optimize?

~ PIO Products LLC